Prototype Information

A railroad's operations is only as good as its personnel, operating plan, and its physical plant (right of way, yards, locomotive and rolling stock).

In order to ensure that each and every spect of operations is efficient, a series of documents outlining that departments operations is maintained. It is the same with the maintenance of way department.

The maintenance of way department is no exception. The department maintains a series of technical specifications on a wide variety of bridges, buildings, tools and track components used withing the railroad company system.

Fortunately there are two excellent sources of this information on the internet.

- Robert Schoenberg maintains a series of Pennsylvania Railroad system Standard MOW plans.

- Don Strack maintains a series of web pages that contains portions of the Union Pacific Common Standards book, a collection includes a large variety standards dating from 1904 to 1985.

Railroads standards were also on occasion mandated by law. I found (somewhere) a consolidated spreadsheet by state and track clearance requirements.

Check out your prototype railroad historical society or web site to see if there are standard plans applicable to your operations.

Modeling Information

- RP-7 Track Centers and Obstacle Clearances

- RP-10 Trackwork - General

- RP-11 Curvature and Rolling Stock

- RP-12 Turnouts - General

As the WWSL is a Class III railroad, Andy (and the NMRA) would expect it have the following generic technical specification:

Curve standards Sharp (2-8-0)

Turnouts

Trackage

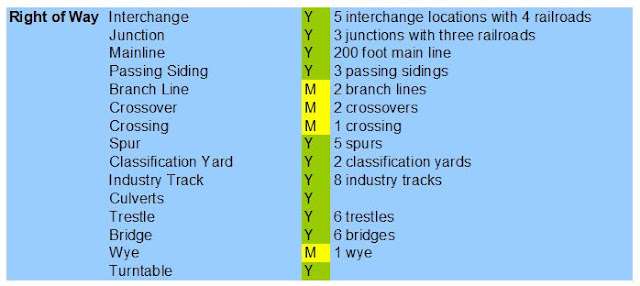

The WWSL

One day the WWSL will maintain a Common Standards book. In the meantime, you'll find those specific standards listed in the WWSL Right of Way Specifications and Modeling section of this web site.

For general planning and construction purposes:

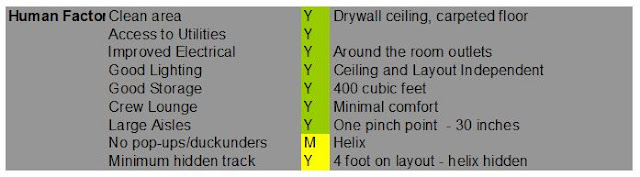

Human Factors. Here are the human factors used to develop the WWSL layout plan.

|

Specification |

In inches |

|

Aisle widths – normal |

48 |

|

Aisle widths – constrained |

30 |

|

Benchwork height – upper level |

56 |

|

Benchwork height – lower level |

34 |

|

Minimum track setback from Aisle |

4 |

|

Minimum track setback from wall or backdrop |

8 |

|

Maximum reach in distance from aisle to track |

27 |

|

Bench work width for shelf style |

24 |

|

Module standard width |

24 |

|

Module standard length |

96 |

Track Planning Standards. The next step was to develop a set of standards for the

trackwork. It would permit operations by virtually all HO scale equipment I would use in WWSL operations.

|

Specification (In inches) |

WWSL |

OPLC |

STC |

|

Typical equipment length |

50 |

|

|

|

Maximum equipment length |

|

|

|

|

Track centers, double track, tangent |

2 |

2 |

2 |

|

Track centers, tangent, Type 2 cantenary pole |

|

|

|

|

Track centers, arrival departure track |

|

|

|

|

Track centers, yard |

2 |

2 |

2 |

|

Track centers, siding industrial track |

|

|

|

|

Track centers, double track, minimum curve |

|

|

|

|

Turnout number, single |

5 |

6 |

5 |

|

Turnout number, crossover |

6 |

8 |

6 |

|

Turnout number, ladder |

5 |

6 |

5 |

|

Track curve, minimum radius, main line |

|

|

|

|

Track center, double track, minimum radius |

|

|

|

|

Maximum grade % |

|

|

|

|

Vertical curve multiplier |

|

|

|

|

Easement |

|

|

|

|

Super-elevation |

|

|

|

|

Minimum over/under track separation |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|