In Layout Design Process 4 - Railroad Modeling I identified that the layout design process can be broken down into three primary functional areas: Concept, Structure and Layout Detail.

Layout Detail. Layout Detail identifies the parameters within which the layout must be designed. It is broken down into two main elements: 5) Layout Design, and 6) Construction to build the railroad.

Layout Detail. Layout Detail identifies the parameters within which the layout must be designed. It is broken down into two main elements: 5) Layout Design, and 6) Construction to build the railroad.

Under the element Layout Design, the following area is considered: Track Plan Analysis.

The WWSL

At this point in time I have collected alot of information through the layout design process.

Some of it is here and some is in the Station Plans.

Layout givens and druthers.

Concept. I am comfortable with the who what where and when aspects of the WWSL version 3.0 I particularly like the idea that i can model the three Class 1's and having the Olympic Peninsula Logging Company and the Saginaw Timber Company live and functioning is icing on the cake.

I believe that Demaine Yard is designed properly for a Division yard and sized appropriately for the amount of traffic going through the yard daily.

The layout design does address my interests in the natural resources industries. 'Keep it Simple Stupid' was the repeating mantra during the given and druthers stage and I think I've juggled those competing balls adequately.

Single Track TT&TO operations can be easily implemented. The absence of a complicated signal system is a relief to me.

An added bonus is the opportunity to model three distinct engine servicing facilities: electric, steam and diesel.

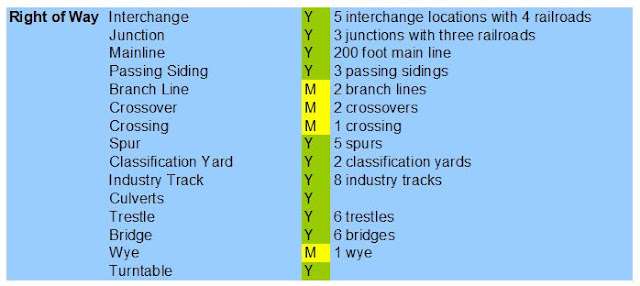

Right of Way. Double decking the layout was the way to go. I am comfortable with the two heights. The turnout count is high but reasonable given the degree of operating capability. Fine tuned commercial turnouts and flex track will speed up track laying. The track plan will have everything necessary for Master Model Railroader certification.

The opportunity to build a myriad of bridges, culverts etc. is icing on the cake.

Scenery. A majority of the layout is flat, with scenic vignettes having most of the more 'difficult' scenery construction. It is however within my abilities. I'm looking forward to using the more modern scenic techniques employed since my construction of version 2.

Catenary/Signal. I've opted at this moment in time to model the catenary system minus the actual wire. Its not that im afraid of stringing wire, its the thought of trying to re-railing rolling stock or uncoupling them that gives me pause. Depending on my experience, I may rethink this decision after the majority of the layout is functional.

Logically it makes sense that a short line would not have any signaling. Research indicates that the NP had an automated crossing with the Shafer Brothers rail crossing at Brady. That would entail semaphores for the NP branch line. I am thinking dwarf signals for the WWSL. The MILW/UP branch line had an automated crossing with the original Saginaw Timber Company. I am thinking dwarf signals for the WWSL there too. I'm looking at a couple of options that could be used to simulate those automated crossings.

Locomotives and rolling stock. I'm looking forward to the opportunities to operate electric, steam and diesel units on the layout. Kitbatching the electric locomotives will be a skill upgrade for me. Steam locomotive operations is new and promising. I have in storage several 2-8-0's and smaller for operations. I've even got a 2-10-2 that could be used. I've got some history to justify it, but its but it's not going to be operational.

I'm pretty happy at the variety of rollling stock that can be used on the layout. I'm also looking forward to the opportunity to detail existing rolling stock and kitbatching existing cars that cannot be purchased.

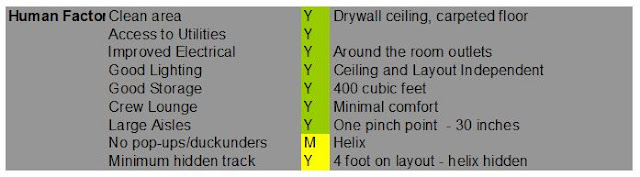

Human Factors. I've always wanted a dedicated railroad layout space. Now I have it and it's met my expectations. Its fun to be down there (compared to other locations where I've had my layouts set up).

Only one place has a aisle pinch point that doesn't meet the aisle parameter of a minimum 36-inch width to provide comfortable movement by crew - the right side of the layout where the workbench is located. Moving the center peninsula leftward was considered however the furnace air runs interfered with the possible construction of a stud wall and the two lally columns in the middle would interfere with personnel movement along the right center peninsula. As it is a quick walk thru area with open space on either end for train control, the pinch point is considered a necessary evil.

Having to duck under to get to the interior of the helix for track cleaning and maintenance is a necessary evil as well. Fortunately I'm still limber!

Layout Design - 8 - Track Plan Analysis (Part 2) will be an analysis of the operational trackage versus numbers of trains, cars, etc.

No comments:

Post a Comment