In 1939 the Milwaukee bought two covered Howe truss bridges over the Chehalis River along the abandoned portion of the line at Mays and Dryad from Weyerhaeuser, and moved them to Park Jct. on the Tacoma Eastern to bridge the Nisqually River.

The WWSL

In the WWSL history, this bridge complex is the second at this location.Engineering

This design is characterized by inward leaning members that are heavier than the outward leaning members. The inward leaning members are in compression. In a static situation (no movement or

shifting of forces), the outward leaning members are not even needed. See Figure 1 for a description of the different parts of a Howe truss bridge.

The top chord is in compression and the bottom cord is in tension. There aren’t many trees big enough to supply large timbers long enough to build these chords

Modeling Information

Fortenberry, Curt. 121' Through Howe Truss Bridge, An Alaska RR Standard. Mainline Modeler, February 1986. Includes engineering plan and bill of materials.

Barrett, Michael C. Modeling Timber Truss Bridges. Michael was President of the Black Bear Construction Co., Inc., who made model bridge jigs and component kits. He passed away in 2018 and the company was dissolved.

I have a bridge clinic

he published before his death, and the web site that it was located on had been lost. I hate it when knowledge is lost and I am in the process of reconstructing that clinic below for your modeling information.

Construction

Almost all timber truss bridges are of the Howe design.

* The author designed and wrote the instructions for this product.

DIAGONAL BRACE ASSEMBLY

TENSION PLATE

TENSION BOLT

PORTAL CAP TOP

U-CHANNEL

TOP CHORD

Bridge Assembly Drawing

LATERAL TENSION ROD

PORTAL BRACE

PORTAL CAP

BOTTOM

TRACK GUIDE

FLOOR BEAM

NBW

STRUT

END POST

ASSEMBLY

VERTICAL TENSION ROD

COUNTER BRACE

ASSEMBLY

BOTTOM CHORD

NBW

Figure 1 – Components of Midwest Products’ Fox River Bridge kit. Notice

that the bridge can sit directly on the floor, table, or plywood. (Used by

permission of Midwest Products, Inc.)

without joints. The joints are generally combinations of cleats, plates, and bolts.

Lots of drawings and photographs are covered in the clinic.

The stresses in the braces and rods are greatest at the ends of the bridge. It is

common for the diagonal braces to be larger in size and the iron rods to be more

numerous as they get nearer the ends of the bridge. It is rare to take the size changes

into account when modeling. Also, the bottom chord was sometimes reinforced by

“scabbing” additional members onto the sides out in the middle of the bridge.

MIDWEST PRODUCTS’ FOX RIVER BRIDGE

Fox River’s “Success Series” instructions are similar to Midwest Products’ offerings

in other product lines. The Success Series Kit instructions contain detailed, step-bystep,

illustrated instructions that virtually guarantee that a modeler with only

moderate skills can build a good-looking, craftsman-quality bridge.

A full size drawing is included in the kit. It is used to build an assembly jig on a

piece of plywood. (The plywood is not provided.) This jig ensures the side panels

are identical and straight. The artwork on the drawing lets you line up the tension

rods so they are all

vertical and parallel.

Using music wire makes

sure they stay straight.

A key feature in the

design of the kit is the

stacking of the elements

(chords, braces, spacers,

and iron rods) in the jig.

The braces are supplied

with a thin “guide tab”

spacer that centers the

brace where it needs to

go. Figure 2 shows how

this guide tab lines up

the diagonal braces and

counter braces with the

elements of the chords

when the parts are

stacked in the jig.

USING THE FOX RIVER IDEA ON OTHER BRIDGES

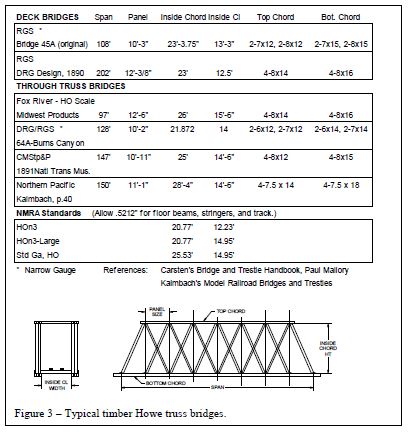

Building the jig and deciding on the sizes of the pieces is the first task. Figure 3

shows key design parameters for several Howe deck and through-truss bridges.

Figure 4 shows typical wood sizes for modeling the Fox River Bridge in other scales.

BRACE

GUIDE TAB

TENSION ROD

JIG

Figure 2 – Brace and guide tab being installed in Fox

River jig.

You do not need a lot of detail on the drawing that is used to build the jig. But you

do need an accurate 1:1 schematic of the bridge. First draw two horizontal lines

separated by the distance that represents the inside chord height. Draw a series of

vertical lines that define the panels. These lines will locate the tension rods and the

end support points. See Figure 5.

Install blocks of wood along the horizontal lines. Place them so they do not interfere

with any pieces of the bridge. Stack up your chord stock and install blocks of wood

on the outer sides of the chords and at the ends of the chords. See Figure 6.

DECK BRIDGES Span Panel Inside Chord Inside Cl Top Chord Bot. Chord

RGS *

Bridge 45A (original) 108' 10'-3" 23'-3.75" 13'-3" 2-7x12, 2-8x12 2-7x15, 2-8x15

RGS

DRG Design, 1890 202' 12'-3/8" 23' 12.5' 4-8x14 4-8x16

THROUGH TRUSS BRIDGES

Fox River - HO Scale

Midwest Products 97' 12'-6" 26' 15'-6" 4-8x14 4-8x16

DRG/RGS * 128' 10'-2" 21.872 14 2-6x12, 2-7x12 2-6x14, 2-7x14

64A-Burns Cany on

CMStp&P 147' 10'-11" 25' 14'-6" 4-8x12 4-8x15

1891Natl Trans Mus.

Northern Pacif ic 150' 11'-1" 28'-4" 14'-6" 4-7.5 x 14 4-7.5 x 18

Kalmbach, p.40

NMRA Standards (Allow .5212" f or f loor beams, stringers, and track.)

HOn3 20.77' 12.23'

HOn3-Large 20.77' 14.95'

Std Ga, HO 25.53' 14.95'

* Narrow Gauge Ref erences: Carsten's Bridge and Trestle Handbook, Paul Mallory

Kalmbach's Model Railroad Bridges and Trestles

SPAN

PANEL

SIZE

INSIDE

CHORD

HT

INSIDE CL

WIDTH

TOP CHORD

BOTTOM CHORD

Figure 3 – Typical timber Howe truss bridges.

It is difficult to cut slits in the sides, or ends, of the braces in a non-production

environment. Therefore, a different method must be used to line up the braces. The

solution lies in using short pieces of the same music wire that is used in the tension

rods.

It is easy to estimate the lengths of the diagonal braces and counter braces. Cut your

material for these pieces. Make them about ¼” too long. Countersink the ends of

each brace with a pointed motor tool bit. Drill holes in the ends of the braces for the

iron rods. Twirl the brace in one hand while holding the electric drill with the other.

FOX RIVER THRU-TRUSS BRIDGE - BUILDING IT IN OTHER SCALES

IN THE KIT O Scale Sizes

HO Scale Sizes Narrow Ga. Standard Ga. S Scale N Scale

Top Chord 3/32 X 5/32 5/32 x 1/4 3/16 x 5/16 1/8 x 7/32 1/16 x 3/32

Bot Chord 3/32 X 3/16 5/32 x 5/16 3/16 x 3/8 1/8 x 1/4 1/16 x 1/8

End Post 5/32 X 3/16 1/4 x 5/16 5/16 x 3/8 7/32 x 1/4 3/32 x 1/8

Diagonal Brace 1/8 x 1/8 .2083 x .2083 * 1/4 x 1/4 5/32 x 5/32 1/16 x 1/16

Counter Brace 3/32 X 3/32 5/32 x 5/32 3/16 x 3/16 1/8 x 1/8 1/16 x 1/16

Portal Cap Top 1/8 x 3/16 3/16 x 5/16 3/16 x 5/16 5/32 x 1/4 1/16 x 3/32

Portal Brace 1/16 x 3/32 3/32 x 5/32 3/32 x 5/32 1/16 x 1/8 1/32 x 1/16

Styrene U-Channel 1/8 3/16" 1/4" 5/32" .080"

Struts 1/16 x 1/16 1/8 x 1/8 1/8 x 1/8 3/32 X 3/32 1/32 x 1/32

Vertical Tension Rods .025 dia music wire .047 dia .047 dia .032 dia .015" dia

Tension Plate .030 x .125 Styrene N/A N/A N/A N/A

Tension Bolt 1/4" Heavy Duty Staple N/A N/A N/A N/A

Lg NBW (Grandt Line) 5093 16 16 5123 5066

Sm NBW (Grandt Line) 5066 5093 5093 5066 N/A

* O Scale 10 x 10 or 7/32" x 7/32"

FOX RIVER PROTOTYPE FLOOR MATERIALS - HO

MUSIC WIRE .025" DIA .047 dia .047 dia .032 dia .015" dia

SPACER .0208" x .1041" .0416" x .125" .0416" x .125" 1/32 x 1/8 .0208" x .1041

STRINGERS 3/32" x 1/8" 5/32 x 7/32 5/32 x 7/32 1/8 x 5/32 1/16 x 1/16

Lg NBW (Grandt Line) 5093 16 16 5123 5066

Sm NBW (Grandt Line) 5066 5093 5093 5066 N/A

FLOOR BEAMS 1/8" x 1/4" 7/32 x 7/16 7/32 x 7/16 5/32 x 5/16 1/16 x 1/8

STRUTS 1/16" x 1/16" 1/8 x 1/8 1/8 x 1/8 3/32 X 3/32 1/32 x 1/32

Styrene U-Channel Midwest P/N M-724 3/16" 1/4" 5/32" .080"

FOX RIVER LAYOUT PARAMETERS

Panel size (inches) 1.724 2.547 3.125 2.344 0.938

Inside chord ht. (inches) 3.586 5.155 6.500 4.875 1.950

Figure 4 – Building Midwest Products’ Fox River Bridge in other scales.

If you have been trying to come up with a reason to buy a battery powered Dremel

tool, this is it. See Figure 7.

Follow these steps to construct the bridge:

1. Place one piece of the top and bottom chord stock in the jig.

2. Cut pieces of music wire to length and glue them in place with CA glue.

3. Cut end posts to rough length. Drill holes in the ends. Cut angles to fit. Insert

pieces of wire. Glue end posts between chords.

4. Cut pieces of diagonal brace stock to rough length.

5. Drill holes in the ends of the braces. Place short pieces of music wire in the

ends of the braces and glue them to the chords using CA glue. See Figure 8.

6. Repeat these steps for all the braces on this layer.

7. Place additional chord material in the jig and continue installing the diagonal

braces or counter braces until the side panel is completed.

8. Build two side panels and install the flooring and bracing to join them together.

SPAN

PANEL

SIZE

INSIDE

CHORD

HT

Figure 5 – Drawing the lines for the jig.

2: GLUE BLOCKS ALONG OUTSIDE AND ENDS OF CHORDS

3: CUT BRACES TO LENGTH

1: GLUE BLOCKS ALONG INSIDE OF CHORDS

Figure 6 – Build the jig by fitting blocks to the chord stock.

CONCLUSION

Many very difficult challenges can be overcome by using the techniques presented

here to build a Howe truss bridge of just about any size. The easy-to-build jig and

registration wires allow the stacking of the components. This gets around the very

difficult task of drilling straight and properly aligned holes. Thus, a great looking

timber bridge is within the reach of any moderately skilled modeler.

COUNTERSINK HOLE

POWERED

DRILL BIT

TWIRL BRACE BACK AND FORTH

WHILE DRILLING HOLE

ANGLE CUT ENDS

WITH WIRE

INSERTED IN HOLES

Figure 7 – Procedure for drilling centered hole in the end of the diagonal and

counter braces.

BRACES WITH

WIRE IN ENDS

Figure 8 – Building the truss bridge with wire “guide tabs.”

Key points to remember:

1. Build two identical side panels.

2. Drill holes in sides of top and bottom chords. Holes on inside are for lateral

tension rods. Holes on outside are for NBW’s.

3. Insert tension rods on one side panel.

4. Glue two floor beams to one side panel. Make sure they are square.

5. Glue the first two floor beams to other side panel.

6. Install rest of floor beams.

7. Slide lateral tension rods into other side panel.

8. Install struts, channel iron, and other details.

References.

Harold Russel that I referred to in my last post, in the Dec. 1988 MRR.

It was actually part 6 of a series that Harold did, starting in July of 1988.

The book Model Railroad Bridges & Trestles contains drawings of a Northern Pacific 150-foot Howe truss bridge.

Fox River Through-Truss Bridge kit

Fox River Through-Truss Bridge -- 11-7/8 x 2-5/32 x 3-1/2" 29.7 x 5.4 x 8.8cm

Midwest Products Co., Inc. - no longer in their catalog

No comments:

Post a Comment