A turnout is an arrangement of track which diverts rolling stock from one track to another.

- The switch is the device for shifting the route at the entrance of a turnout.

- The rails connecting the switch with the frog, in both main track and turnout, are lead rails, (alternatively named the main lead and the turnout lead).

- The frog is the union of two rails which cross each other, in such a manner that a wheel rolling along either rail will have an unobstructed flangeway while passing the other rail.

There are three types of switches: stub, Wharton, and split switch.

- A stub switch is a railroad track switch that lacks the tapered point rails of a conventional switch. The movable rails and the ends of the rails of the diverging routes have their ends cut off square. The switch mechanism aligns the movable main line rails with the rails of one of the diverging routes.

|

| Stub Switch |

- The Wharton switch is not used today. The main track rails are unbroken and continuous. The switch rails consist of one point or grooved rail, which works against the main-track rail on the side opposite the frog, and another rail to which it is cross connected, working against the outside of the main-track rail on the frog side.

- The split switch is made up of a rail from each track, both rails being tapered a long way back and connected together, so as to throw alongside the through rail of either track. The split switch is the most common switch type used by the prototype today.

The railway frog consists of two point rails, two wing rails, two guard rail (also named check rail), tie plate, blocks, other accessories and etc. According to different production technologies, Frog may be classified into different types.There are two types of frogs: rigid and sprung.

- The rigid frog is the most common frog found on railroads. In a rigid frog all the parts composing it are supposed to be rigidly connected. The parts of both rigid and spring-rail frogs are joined together in three different ways: ( 1) by placing filler blocks between the pieces of rails and holding them together with bolts passing through the webs; (2) by riveting the flanges of the pieces of rails to a plate; and (3) by clamps or by clamps and wedges.

- The sprung frog is found on main line tracks, and especially for those sections where the heavy traffic moves principally in one direction. It gives to the main line the smoothness of an unbroken track. In an ordinary spring-rail frog the wing which takes the bearing of wheels on main track is movable, and, except when it is spread by the flange of a wheel passing through the turnout, it rests against the point pieces. With such a frog there is normally but one channel. As successive wheels pass the movable wing, or "spring rail," as it is called, is pushed aside by the flanges and returned to normal position by the spring.

Turnout Geometry

Turnout comes in various sizes, the geometry based on the degree of curvature of the diverging route. The degree of curvature is identified by the frog number. A turnout has its unique engineering to determine the degree of curvature but for simplification purposes, the frog number is a 'rise-run' calculation - a No.6 frog diverges one unit for every six units of length. The smaller the number, the sharper the curve. The Union Pacific has a Common Standard for No 6, No 7, No 8, No.9, No 10, No 12 and No 14 turnouts.

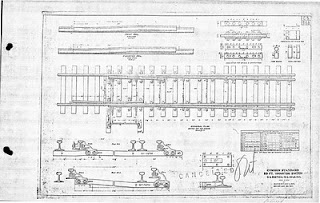

Here is an example of the UP Common Standard No 6 turnout.

The frog number also determines the maximum speed through the turnout. Here is a chart of frog number and authorized maximum speed from the AREMA.

switch points, referred to as "switch stands", may be used in main tracks, branch lines and secondary

tracks, yard and sidetracks, without restriction.

also provide for locking them in normal and/or reverse position, referred to as "locking switch

stands", may be used as follows:

wheels trailed through a switch set for the opposite route, and referred to as "semi-automatic switch

stands", may be used in yards and sidings where authorized by Timetable Special Instructions.

when the switch is set in normal position in main track, and at the siding end of crossovers between

main track and siding.

(e) Switch stands for all other tracks shall be located to serve the safety and efficiency of

employees in the best manner. Switch stands are normally located on the divergent side of the turnout. When necessary for safety or other good reason, switch stands may be placed on main line side of track.

spring switches

Straight vs curved tracks - to avoid confusion model railroad wye turnout can be used in prototype railroads - the UP calls them crotch turnouts

Location of Crotch Frog.—A crotch, or middle, frog is a frog placed at the point where the outer rails of both turnouts of a three-throw switch cross each other. When both turnouts are of the same degree, the crotch frog comes midway between the main track rails. Its location and angle may be determined as follows: Let the turnout curves A and B, Fig. 545, be each 9° 30', uniting with the main track C by a three-throw switch. Let a be the P. C. common to both curves, and b, the location of the crotch or middle frog.

No comments:

Post a Comment